In the rapidly evolving world of apparel manufacturing, staying ahead of the curve is vital. A robust Enterprise Resource Planning (ERP) system can be the backbone to streamlining operations, improving efficiency, and maximizing profitability. As we approach 2025, manufacturers must analyze the latest ERP solutions tailored to their specific needs. From {demandplanning to production automation, a top-tier ERP system can transform your apparel business.

- Take a look at some of the leading ERP systems

Elevating Garment Export Efficiency with ERP in 2025

Garment manufacturers are facing unprecedented demands in a rapidly evolving global marketplace. To remain competitive and profitable, businesses must streamline their operations and leverage the latest technological innovations. Enterprise Resource Planning (ERP) systems are emerging as a powerful tool for garment manufacturers to achieve these objectives. By implementing an How can ERP systems handle fabric and raw material inventory for garment manufacturers in 2025? integrated ERP solution, businesses can accelerate key processes such as procurement, production planning, inventory management, and order fulfillment. This leads to enhanced efficiency, reduced costs, and ultimately, higher export performance in 2025.

Consequently, ERP systems empower garment manufacturers to gain a significant competitive advantage by promoting greater visibility, collaboration, and agility across their entire supply chain.

Essential ERP Features for Apparel Manufacturers in 2025

As the apparel manufacturing industry continues to evolve rapidly, adopting a robust Enterprise Resource Planning (ERP) system becomes paramount. In 2025, key ERP features will be vital for manufacturers to remain successful.

Foremost among these are: real-time inventory visibility, allowing manufacturers to optimize their operations and respond swiftly to market demands. A powerful PLM (Product Lifecycle Management) system will be indispensable for developing innovative products, while integrated production planning and scheduling features will maximize efficiency and minimize downtime.

Furthermore, a modern ERP system should provide robust data analytics capabilities, enabling manufacturers to gain valuable insights from their operations. Additionally, integrations with e-commerce platforms and third-party applications will be fundamental for streamlining end-to-end business processes.

ERP Implementation Expenses in Garment Manufacturing (2025)

Predicting the cost of ERP implementation for garment manufacturers in 2025 is a challenging task. Many factors will influence the final amount, including the magnitude of the manufacturer, the sophistication of the chosen ERP system, and the scope of customization required. However, industry analysts predict that the average implementation cost for garment manufacturers will fall in the range of \$50,000 to \$250,000 . This band can vary significantly depending on the particulars of each implementation project.

Emerging ERP Trends Transforming the Apparel Sector in 2025

As we venture into 2025, the apparel industry is poised for radical transformations driven by evolving consumer expectations. At the heart of these shifts lies ERP solutions, which are evolving to accommodate the industry's unique requirements. Innovative apparel brands are implementing next-generation ERP systems that offer a integrated view of operations, from production to sales.

- A key trend shaping the apparel industry's ERP landscape is the growing demand for real-time insights.

- This, ERP systems are incorporating advanced analytics and business intelligence to provide retailers with a 360-degree view of their operations.

- Moreover, the industry is experiencing a move toward hosted ERP solutions, offering enhanced flexibility, scalability, and cost efficiency.

Consequently, these innovations are facilitating apparel businesses to perform more efficiently and adapt to the ever-changing market conditions.

Accelerating Growth: ERP's Role in Apparel Manufacturing Triumph in 2025

In the dynamic apparel industry of 2025, creating success hinges on agility, efficiency, and data-driven insights. Enter Enterprise Resource Planning (ERP) systems, a transformative force revolutionizing apparel making. By unifying operations across the entire supply chain, from design to delivery, ERP empowers apparel manufacturers to succeed in an increasingly challenging landscape.

Furthermore, ERP unlocks growth by:

- Optimizing key processes, such as production planning, inventory management, and order fulfillment, enhancing productivity and minimizing operational costs.

- Providing real-time visibility into inventory levels, enabling data-driven choices.

- Facilitating collaboration and communication across departments, fostering a seamless workflow.

As the apparel industry continues to evolve, ERP will be indispensable for companies seeking to thrive. By embracing this technology, apparel manufacturers can achieve sustainable growth in 2025 and beyond.

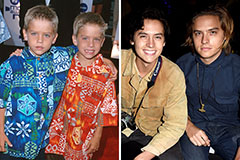

Dylan and Cole Sprouse Then & Now!

Dylan and Cole Sprouse Then & Now! Michael J. Fox Then & Now!

Michael J. Fox Then & Now! Michelle Pfeiffer Then & Now!

Michelle Pfeiffer Then & Now! Jeremy Miller Then & Now!

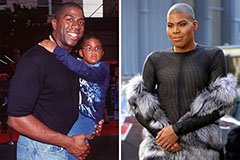

Jeremy Miller Then & Now! Earvin Johnson III Then & Now!

Earvin Johnson III Then & Now!